Products

Ball Bearing

Ball bearings are the most widely used type of rolling bearings, available in various types such as deep groove, angular contact, self-aligning, thrust, and seat-mounted spherical ball bearings, each designed for different load conditions. C&U manufactures ball bearings with inner diameters from 1mm to 6000mm, serving industries such as motors, power tools, automotive, construction machinery, fitness equipment, medical devices, and IT.

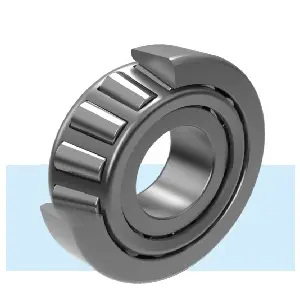

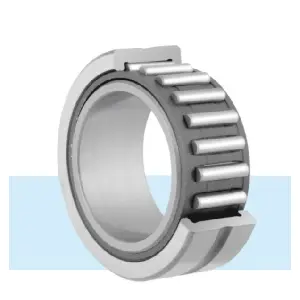

Roller Bearing

Roller bearings are a widely used type of rolling bearing in modern machinery, relying on rolling contact between the main components to support rotating parts. They are largely standardized and offer advantages such as high load capacity, excellent rotational accuracy, and ease of selection.

Automotive Bearing

Automotive bearings include a variety of types such as deep groove ball bearings, tapered roller bearings, wheel hub unit bearings, short cylindrical roller bearings, needle bearings, rocker arm bearings, and shock absorber bearings. Many of these bearings feature unique structures and functions, with proprietary technologies, and are used in key systems of vehicles including the power system, transmission system, steering system, chassis system, and auxiliary systems.

In the power system, bearings are employed in components like engines, generators, tensioners, and water pumps. These bearings are designed for extreme conditions, offering high temperature tolerance, superior low-temperature startup performance, low noise, minimal vibration, and long service life.

For the transmission system, which includes the gearbox, driveshaft, and differential, deep groove ball bearings, needle bearings, short cylindrical roller bearings, and tapered roller bearings are commonly used. These bearings are resistant to contamination, provide low noise, low starting torque, and can handle both radial and axial loads, ensuring long-lasting performance.

In the steering system, specially designed deep groove ball bearings are primarily used in Electric Power Steering (EPS) motors. These compact bearings have low axial play, self-aligning capabilities, can endure bi-directional axial loads, and offer low starting torque, low noise, and extended service life, making them ideal for modern electric steering systems.

For the chassis system, bearings are used in wheel hub units (generations I, II, and III), short cylindrical roller bearings, large cone angle tapered roller bearings, and special shock absorber bearings. These bearings are built for durability, offering impact and fatigue resistance, with significant advantages in replacing imported components.

In auxiliary systems, such as windshield wiper motors, seat adjustment motors, and window lift motors, miniature deep groove ball bearings are typically used. These bearings are known for their low noise, low vibration, and low starting torque, contributing to improved vehicle comfort and overall quality.